Say you’ve decided that pressure forming is the right process for your next plastic manufacturing project. How do you choose the right company to pressure form with?

While we’re obviously not a neutral party in this situation, we do have some advice that will help you get on the right track.

Price Matters

It’s not a bad idea to get your first project quoted by multiple pressure formers. If you’re not familiar with the industry and what things should cost, it can help to make sure that you’re not being taken advantage of.

But it’s important to make sure you’re considering more than just the total at the bottom of the quote sheet.

How much would it cost you if you didn’t meet your deadline? What about the cost of changing your mold because of unexpected problems? Or the costs of production defects?

Look at price, but remember that the cheapest quote you get up front, might not offer the best value in the end.

Technology Matters

The first patent for thermoforming was filed in 1938, but you certainly wouldn’t want to use a manufacturer whose factory was filled with equipment from 70, or even 17 years ago.

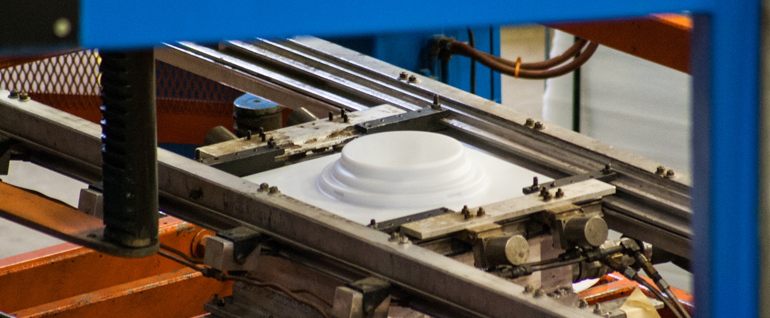

The quality and capabilities of the equipment your pressure-forming manufacturer uses will play a big role in the tolerances, aesthetics and performance of the final part.

At a minimum, you should pick a manufacturer that uses liquid-cooled aluminum tooling, fully-robotic trimming and highly precise 3D coordinate measuring machines.

Size Matters

Even if you aren’t pressure forming particularly large parts, choosing a manufacturer with large part capabilities gives your project the edge. With large part capabilities, you have the option of forming multiple separate parts from a single mold, which can often save both time and money.

You also have the flexibility of combining multiple, smaller parts into single larger part to increase strength, improve aesthetics and cut finishing costs.

Reputation Matters

There’s no Yelp for pressure forming manufacturers (side note, “Yelp for Pressure Forming” has to be a $million idea for the next big app I’m sure). Finding out what other customers have experienced can be a bit more of a challenge.

Longevity is a good place to start. It’s hard to last long in this industry without doing good work, and making your customers happy. If a pressure forming manufacturer has been around a long time, that’s a point in their favor.

Most importantly, ask for references. Then contact them. Ten minutes on the phone with a few customers of the pressure former you’re considering will give you a pretty good idea of how they treat their customers.

Fit Matters

In our world, “fit” can mean two things.

First, fit can refer to specialization and experience relevant to your project. Does the manufacturer you’re considering understand the needs of your industry? Do they have experience with similar projects? Do they have the experience to identify, and solve problems before they happen?

Second, fit can refer to something much less tangible. We believe wholeheartedly in doing business with people we like. Business is personal. If you get along with your thermoforming manufacturer, we can guarantee you’ll have a better experience, and a better outcome, than if you don’t.

Making the Best Choice

There’s no magic bullet to choosing the right vendor every time, but if you use these criteria to evaluate potential pressure forming manufacturers for your next project, you have a good chance of success. And there’s also a good chance that Ray Products will be in the running