In this Plastics Industry Pulse, we’ll ask some questions about the 2019-2020 Annual Report data on changes in process popularity, with a special eye on injection molding.

Did you know: This is the sixth year that we’ve collected data on Process Popularity in the Plastics Industry.

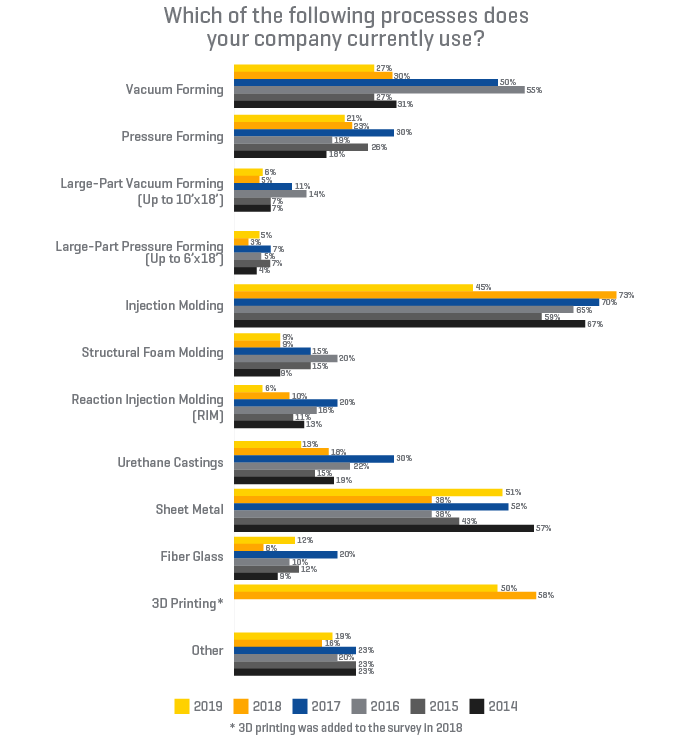

Looking back on previous years as a comparison, this year’s data demonstrates a marked change in the popularity of injection molding. Over the last four years, respondents have indicated a growing interest in injection molding (59% in 2015, growing to 73% last year), while this year it took a 38% year-over-year dip to plunge to only 45%. Time will tell if this is just a statistical anomaly or if this represents an ongoing trend.

Connecting Process Popularity & Total Project Cost

Likewise, both vacuum forming and pressure forming are also down significantly from past years, while sheet metal and 3D printing are holding steady in Process Popularity. See Chart 1 below for more.

While we all know that causation does not necessarily mean correlation, since processes like sheet metal tend to have lower startup costs (over injection molding for example), there may be a connection here to respondents’ desire for cost savings, which would be consistent to what we have noted elsewhere in the data. In particular, as mentioned in our previous Pulse, respondents put total project cost as the number one challenge for plastic manufacturing, which could connect with the increase in popularity of items such as sheet metal in the overall process popularity data.

In the next Plastics Industry Pulse, we’ll examine how thermoforming popularity compares by industry and why that matters.

As always, we’re happy to share the report with you, and it’s absolutely free.

You can download it right here.