3D printing is big news, and it’s no wonder. Just a few years ago, the idea of printing directly from a CAD file to a 3D physical object in a matter of minutes was preposterous. Today, it’s entirely possible.

With so much coverage in the press and popularity online, we’re sometimes asked, “Is 3D printing cutting into your business?” The very truthful answer is, not at all. In fact, it can be quite helpful.

You see, 3D printing is excellent at what it does, but what 3D printing does is quite different from what thermoforming does.

Thermoforming is a very cost-effective process once you’re planning to produce quantities of a few hundred parts up into the mid-thousands. When potential customers ask us to produce a single prototype, we usually refer them to 3D printing or other prototyping processes to help ensure manufacturability in thermoforming. This way, when they’re ready for that production run, there’s going to be no question which method is right for them.

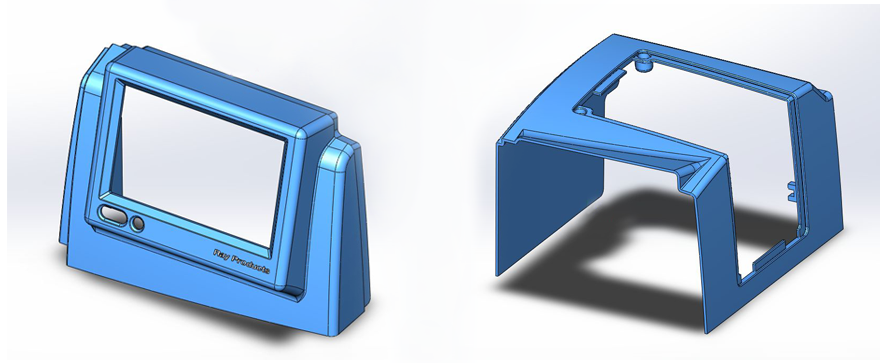

Let’s look at a real-world example. This is a desktop equipment enclosure that we designed for a trade show display. We sent out the files to a respected 3D printer that some of our clients use for prototyping. Their quote was around $3000, manufactured in ABS-M30. If you’re making a single high-quality prototype, that’s a very reasonable cost.

At a quantity of 100, we quoted the same part at the cost of around $150 each, manufactured in UL 94 V-0 material with Microban antibacterial properties. At a quantity of 100, thermoforming is less than 1/16 the cost of 3D printing.

Just looking at cost-at-quantity, it’s clear that 3D printing and thermoforming aren’t competing for processes. There’s no sense in thermoforming a one-off prototype, and no reason in 3D printing a more significant production run.

And there are other differences. Nick Allen, the founder of a 3D printing company himself, wrote an excellent article that outlines some of the limitations of the process.

So, how can 3D printing be an asset to your next thermoforming project? By offering an affordable way to produce physical prototypes before tooling.

For many thermoforming projects, going straight from CAD files into tooling and production is an easy and straightforward process. For others, projects that are more complicated or projects that may be trying something new and untested, and a physical prototype is worth creating.

Physical prototypes can help communication and help troubleshoot future problems before you invest in tooling. Your product engineer can probably learn everything they need to know by looking at a rendering on their screen, but what about your shipping and logistics team, management, marketing, or even potential customers? Having a physical prototype can often lead to valuable feedback before you move into production.

It can also help to plan your manufacturing process. Sometimes a physical prototype can save hundreds of hours in preparing for things like attachment points, undercuts, tabs, and other more sophisticated features.

The ability to inexpensively 3D print a prototype of your part, or even a specific section of your piece, before moving into production can significantly reduce headaches down the road.

We don’t stay awake at night, worrying that 3D printing is stealing away customers. It’s not, and it won’t. Instead, we rest a bit easier, knowing that 3D printing gives our customers and us another tool to help plan and execute successful thermoforming projects.